Immediately after machining parts/components, CNC precision machining grinders are one of the final manufacturing operations. Abrasive grinders (or wheels) are used in CNC precision machining grinding to supply a precisely flat area having a smooth end on machined objects.

It has grown to be the ought to-have technology for complex CNC machining tasks that should work in tandem. When perfection is required at a microscopic degree, each and every millimeter issues. The only real way to attain this perfection is through precision machining.

The automotive industry is without doubt one of the major sectors for CNC machining. CNC machining features advantages at each and every stage in the automotive manufacturing system, from prototyping in Exploration and Advancement (R&D) to producing large portions of parts.

Reduced Human Mistake: CNC machines’ automation minimizes human mistake significantly, with precision programming assisting lessen faults for increased trustworthiness in significant-stakes manufacturing environments.

Unilateral Tolerances: In this sort of tolerance, variation in Proportions is permitted in a single course. The tolerance limit can either be earlier mentioned or under the intended dimensions.

Metals: Metals such as aluminium, metal, titanium and copper are used due to their sturdiness, energy and flexibility. Just about every metal features exclusive traits; aluminium’s lightweight nature may attract some, when titanium delivers power and corrosion resistance, for instance.

Specialized niche manufacturing industries are certainly not huge like those outlined thus far. However, They are really smaller to medium-scale manufacturing amenities dependent on CNC machining for dependable parts.

Numerical machines are programmed having a set of instructions that go ahead and take type of letters, quantities, and symbols. Punch cards are used to ability NC machines. NC Machines comprise some elementary parts.

CNC machines have already been utilized in construction and agriculture For the reason that 1980s, in the beginning for manufacturing straightforward components. Over time, the technology has advanced to empower the production of additional complex parts, strengthening the functionality and trustworthiness of construction and agricultural machinery.

The change towards renewable energy resources has pushed click here even further innovation in CNC machining, specifically during the production of wind turbines and solar panels.

Anodizing: A means of forming a layer of oxide movie on aluminum products and solutions, to beat the defects of aluminum alloy surface area hardness and dress in resistance.

Bredikhin also sought to create the machines readily available for a secretive Russian effort and hard work to mass-create the attack drones which have unleashed horrors about the U.S.-backed Ukrainian Military, In keeping with an invite sent to one of many project professionals overseeing motor construction for the drone software.

A cutting tool is really a kind of instrument made to Lower or condition many materials, especially Wooden, plastic, and metals. Specially inside the Manufacturing Industry, these tools are greatly used for material removal processes. A Browse far more…

For moveable machining operations involving a few to numerous axes, CNC machines are usually used. Computer computer software is usually used to deliver programming or work Recommendations, that are enter directly into CNC machines.

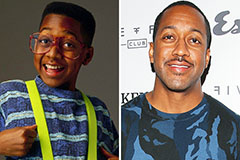

Jaleel White Then & Now!

Jaleel White Then & Now! Jennifer Grey Then & Now!

Jennifer Grey Then & Now! Jonathan Lipnicki Then & Now!

Jonathan Lipnicki Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Stephen Hawking Then & Now!

Stephen Hawking Then & Now!